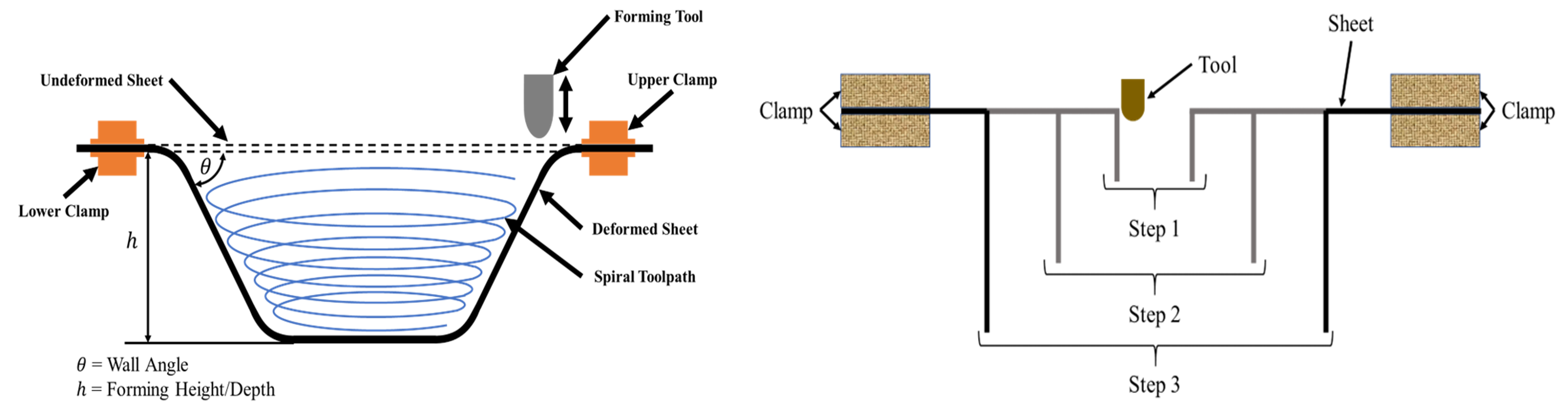

Development of heat-assisted incremental forming technology

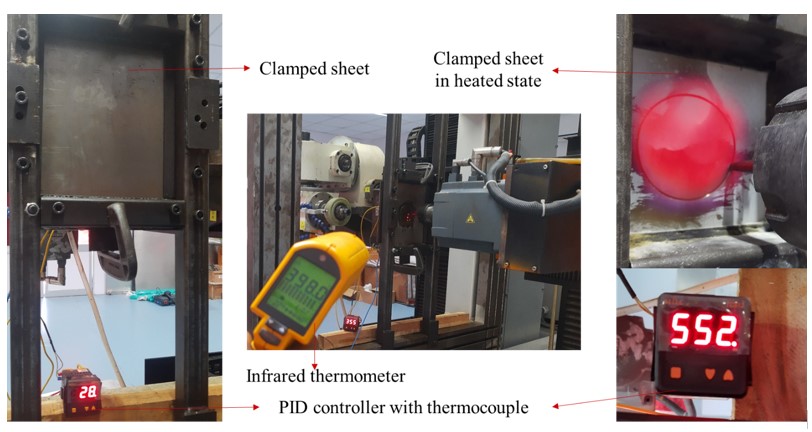

The heat-assisted incremental forming (Ha-IF) technology can be applied to form the components from hard-to-form materials such as titanium alloy, magnesium alloy, and Inconel alloys. The addition of in-process heating to the incremental forming process provides better formability and geometrically accurate products.

Smart Additive Manufacturing

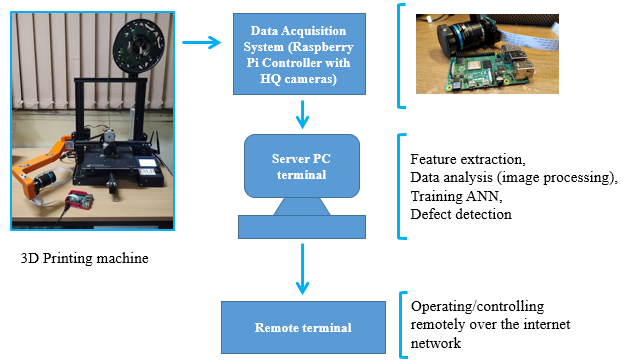

With the use of metal filaments or metal feedstocks, the fused filament fabrication (FFF) technology can be transformed into a metal additive manufacturing (MAM) process. The weakness of MAM is the generation of some defects that weakens the mechanical properties and, in some cases, these defects may lead to the part failure. Therefore, identification of such defects is very crucial for ensuring the desired geometrical accuracy in the 3D printed part being fabricated. The extrusion-based MAM is not yet widespread, but published scientific and technical literature on it is rapidly growing. The entire work aims at developing a Cyber-Physical System (CPS) for the extrusion-based MAM technique so as to identify the associated geometrical defects, and monitor and control the process remotely.

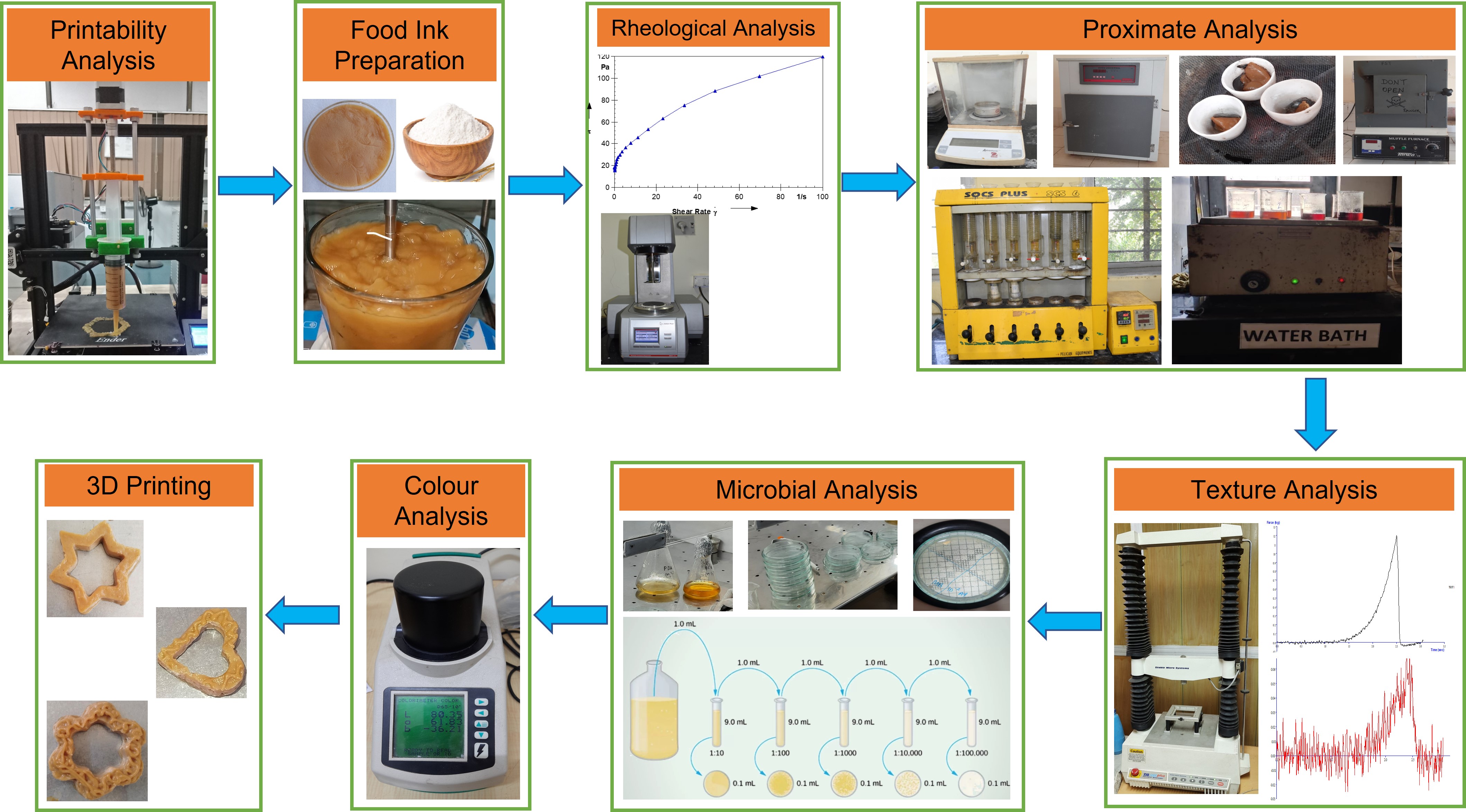

Food Layered Manufacturing

Additive manufacturing is a digitally controlled, robotic construction process which builds up physical object layer by layer directly from a CAD model. When this technology is applied to the foods, it is known as food layered manufacturing. FLM is a new process for constructing solid foods. In this process, food grade syringes hold the printing material, which is then deposited through a food grade nozzle layer by layer. By using this technique, we can customize the food in shape, color, texture, flavour or nutrition, which makes it very useful in various fields such as space exploration and healthcare. Main goal is to create customized and texture modified foods. Low-cost nutritious food will be identified. Alternative resources and eco-friendly materials will be used to create healthy and nutritious foods to provide foods to those who are not able to get the foods properly. Strategies will be proposed for mass production and for low-cost manufacturing of nutrient-rich foods for personalized dietary requirements of persons with critical health disorders/deficiencies.

Hybrid Manufacturing Processes

Currently, we are working in the domain of Hybrid Manufacturing Processes, where our primary objective is to combine two or more processes through their process mechanism to achieve a similar effect in a single setup. We are working on Incremental Sheet Hammering (ISH), Incremental Hole Flanging (IHF), and an Additive Manufacturing-based Forming Process. In the ISH process, we are trying to integrate the hammering and incremental sheet forming processes. In the IHF process, we are trying to integrate the flagging operation with the help of incremental forming approaches. Whereas in the additive manufacturing-based forming process, we are trying to incorporate the hammering motion on the additive manufactured products to achieve a better part density in ceramics

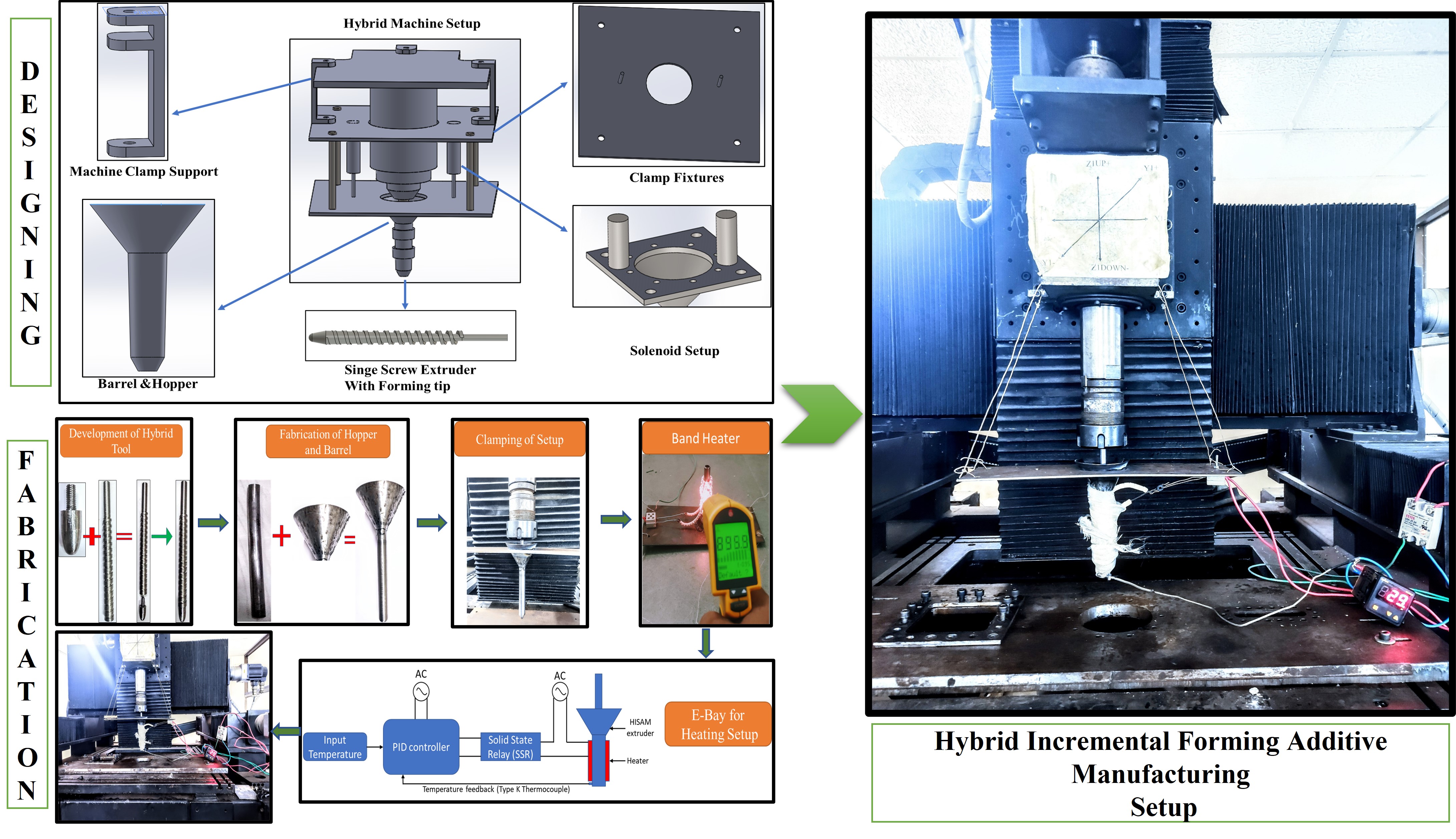

Development of Hybrid Incremental Forming Additive Manufacturing Technology

Under the Hybrid Manufacturing domain, we are currently working on the development of an integrated setup for additive manufacturing and incremental sheet forming. where layer by layer AM is done and simultaneously ISF is performed in a single integrated setup which develops of new process route to manufacture more complex and higher quality parts in a more flexible manner.